An often asked question of how to Speed up 3D prints is most likely a concern for many in the software-hardware based industry.

While, that is possible, not everyone knows how, in a way that it doesn’t negatively impact the printing quality, which makes this article pretty necessary.

For anyone seeking to know how to speed up 3d prints, reasons could range from just updating knowledge and tech know-how to saving tome, to productivity increment etc.

Whatever your reasons, this article provides a number of approaches to guide you on how to speed up 3d prints.

By using a number of hardware and software adjustments you can speed up your printing without risking the printing quality and success.

Though, there are some effects that this type of printing may leave on your project. All of which we will be looking at in this article.

What is Print Speed?

Print speed simply refers to the speed (calculated in mm/s) whereby the print head moves during printing.

Print speed can be adjusted in your slicer software’s settings, this will enable you to print faster. While, fast prototyping is usually possible with a 3D printer, sometimes a higher 3D printing speed is preferred.

Although, the increment in your print speed without effecting other adjustments will most likely result in a worse quality final product, depending on what you are creating.

Also, worthy of note is that the higher you can push this setting will mostly depend on your printer, and how much time you have spent tweaking other settings for the best possible results.

Ways to Speed Up 3D Prints

1. Adjust default 3D print speed

One of the most preferred way is to adjust and customize your 3D print speed in the settings of your slicing software.

When the dddrop EVO Twin was developed, the control of the speed of the print head was a vital starting point.

This brought about perfect acceleration and deceleration of the print head, which ensures neat 3D-printmodels and efficiency in print speed.

You can opt to increase the overall print speed significantly without doing any damage to the quality of the 3D-model, including those with sharp corners.

Also, with a straightforward product, you can increase your 3D printing speed even more.

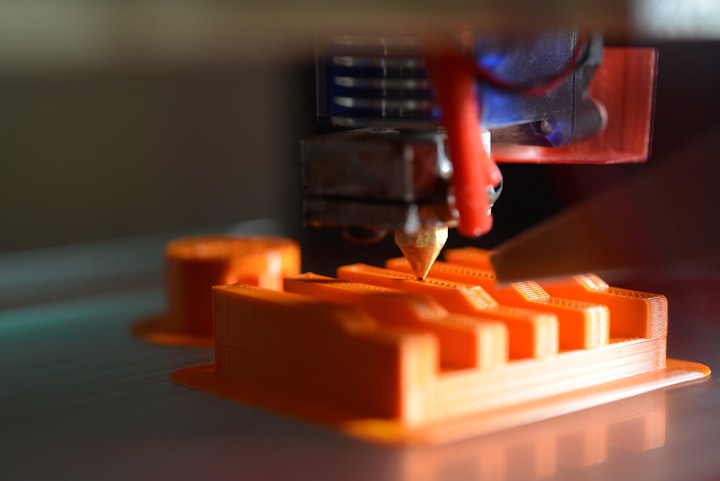

2. Use a Large nozzle and bigger Layer height

To opt for a faster 3D printing, you may want to have a look at the nozzle on your 3D printer. The larger the nozzle, the lower the print time and vice versa.

Large nozzles allow for more material to be extruded through it at once, meanwhile, can print with higher degrees of precision.

Illustratively, it means that a 0.8mm nozzle, will be capable of higher print speeds than a print speed set at 0.25mm nozzles.

If accuracy is not your focus, you can opt to print with a larger nozzle and maximum layer height.

Striking a balance between precision and speed is the standard 0.4mm nozzle, which is often seen as appropriate for 3D printing.

Though, different prints, have different needs, so you need to ensure that you pick the nozzle that is best tailored to address your needs before starting your project.

Also, printing with thicker layers mean a higher loss of detail. dddrop offers the right nozzle for all jobs: it is super detailed or super-fast and you can choose from the print heads: 0,2 – 0,4 (standard) – 0,6 – 0,8 – 1,0mm.

3. Infill Density and Wall Thickness

Another point to note is infill Density and Wall thickness as you speed up 3D prints. Solid prints are made of thicker and stronger outliners filled in with honeycomb structure.

If this structure is unused, the 3D print will take a longer time to complete.

However, if you use an infill, to increase your 3D printing speed, try to reduce your infill even more, but ensure that the ratio between the wall thickness and infill remains good.

NOTE: A product with low infill density and small wall thickness is more vulnerable. So, this technique is most ideal – only with products where strength is not an important factor e.g prototyping.

4. Producing in the same batch

When you are looking at getting two products finished as soon as possible for a client, printing both products in the same batch may be perfect.

Both products can be finished fast, though this is only possible when both products are small enough to fit perfectly on the print bed.

To perform this step, do the following:

- Use the function center and arrange in your slicing software.

- Once that is done, you can producing in the same batch.

- Use the same filaments for both products to prevent heat problems. You do not need to reset your printer.

- It provides more convenience and saves time.

- This is an indirect way to increase your 3D printing speed.

5. One material, Two purposes

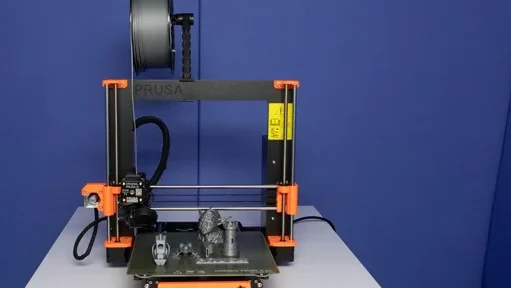

The dddrop EVO Twin 3D printer has 2 independent print heads. Therefore the printer is able to print multi-colour and multi-material.

This means you can print a model of PLA and use soluble support material. However, the printer has to switch between 2 materials. Certainly when in each layer 2 colours are processed, it will take a lot of time.

A solution to increase indirectly your 3D printing speed is to use 1 material for both purposes, so using PLA material as the main material as well as support material.

This is a function in your slicing software. The PLA support material will be printed with a lower infill density, so afterwards it is easier to remove.

In this way the printer doesn’t have to switch between 2 materials and this will save you a lot of printing time. More about printing with support material you will read here.

Conclusion

When you increase your 3D printing speed, it will have an effect on your final product but these effect can be managed by a matter of knowing your scale of priorities.